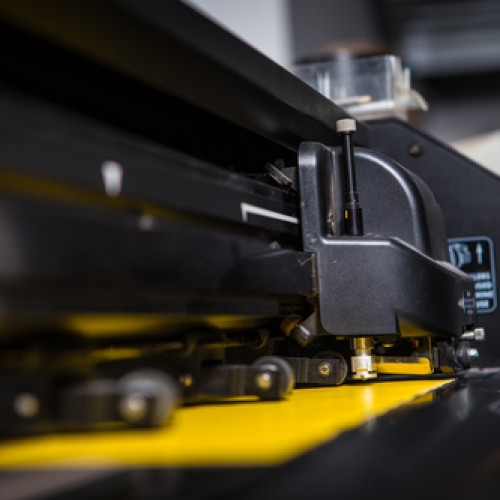

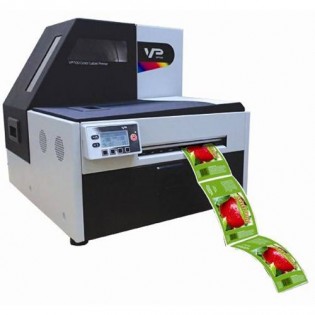

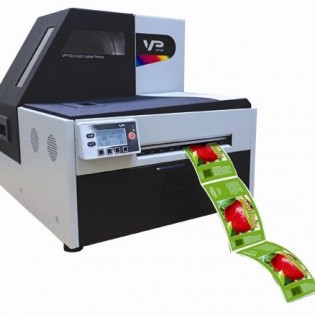

Digital printing produces high quality labels that are vibrant and can be used for any project. Digital printers like the VP 700 memjet digital label printer can be used to print labels for many applications including specialty food, water and beverage, health care and beauty, nutraceuticals and bath and body products among others. When compared with other conventional printing methods, digital printing brings out a much better print dot quality when it is magnified under a loupe. This means that with digital printing, quality is not compromised. During label printing, ink does not absorb into the paper material and neither does it expand on the film printing material. This ensures the digitally printed dot retains the desired size and shape on the original art file.

Making labels using digital printing is all done in ‘one shot’ where all colors are printed at one time, which brings out perfect registration without any trap lines. This process has made digital printing far more advanced and the most ideal solution for most labeling projects, making digital printing nothing short of amazing.

Why Opt For Digital Printed labels?

Digital printing creates eye catching labels that that grab a buyer’s attention, encouraging the customer to engage with the product and make a purchase.

Digital Printing: Environmental Friendly Print Process

Digital printing enables you to minimize your label materials setup time and helps you print your labels more efficiently while reducing the amount of waste than other conventional printing methods. Almost all digital printing inks are recycled and reused in the label printing process, making digital printing an environmental-friendly option.

Why Digital Printing is Ideal For Your Labeling needs

Design Flexibility: The cost of printing labels using other methods like on a flexographic press can be very costly due to plate charges and setup fees. If you’re printing multiple label designs, the costs increase. Digital printing has no plate or setup fees which enables you to print your labels at any given time at lower costs.

Price: As mentioned earlier, digital printing the cost of printing labels is lower compared to other conventional printing methods. The cost per label reduces since there is no setup fees charged.

Quick turnaround: Digital printing requires no plates, which means there is no need for setup when printing full color labels. This means that your labels are printed so much faster and you receive your labels on time.

Short run labels capability: This is a benefit that mostly applies for small quantities of custom labels, also referred to as ‘short run labels’. Digital printing allows you to print the amount of labels you want at that time, rather than ordering large amounts of labels just to get the best price.

Digital printing is very popular across many industries because it is capable of printing 500 – 5000 custom labels with every individual label containing different printed information. This is known as variable data printing which has opened many opportunities to advance the printing of labels. With variable data printing, you can add consecutive numbers, names, multiple barcodes or print many copies and versions of the same label.