While automatic labeling is fast and efficient, problems may sometimes appear. The labeler is the primary device used for a label application, and it may be automatic or semi-automatic. Common problems which may appear include situations where the label is not applied correctly, which mean that there is an issue with either the application equipment or the printer itself. Below are some additional problems that you’ll encounter when applying labels, along with some solutions.

Clear Label Not Being Applied

The majority of applicators make use of a light and dark sensor in order to detect the gap within the labels. To solve this issue you will first want to print a black timing (also known as an eye) on the liner’s backside. You also have the option of selecting a sensor which is ultrasonic that uses sound waves to detect label gaps.

Application Results In Line Tears

When this happens it is often a sign that the applicator tip might need to be repaired or replaced. It may also benefit from UHMW (Ultra High Molecular Weight) tape. This tape is highly slippery and is akin to Teflon. Sometimes tiny tears on the paper liner side are a result of the label plant.

Die Strikes

Die strikes are the most frequent problem you’ll run into when applying labels automatically. The tools used for die cutting labels have high precision, but will eventually wear out. Once this happens the tooling must be repaired, replaced or sharpened. Die gauges can also be added to the press to detect if they’ve become worn.

During Application, The Label Follows The Peel Tip

There are a number of things which can cause this problem. The label plant die strikes might have deteriorated, the applicator’s tension might not be high enough or the applicator is webbed incorrectly. These issues should be evaluated by a specialist and you should inquire as to whether the label plant uses measuring gauges with the press to monitor these things. Sometimes problems can result when the weight of the adhesive coat or void is not what it should be.

Types of Equipment You’ll Need For Efficient Label Application

Using high quality equipment will often prevent many of the problems mentioned above. Labels can be printed through machines that are semiautomatic (where a human does some of the work) or a fully automatic machine (where the machine does all or most of the work exclusively). You’ll need conveyor systems that can move the merchandise to the location where the label will be applied, and it will then be necessary to place the package in the specific position so the applicator can do its work.

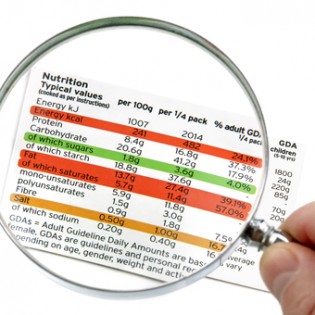

Other types of services that are associated with label printing include consulting and parts, repairs and installations, equipment sales, machines for rent and troubleshooting services. Label application machines are a necessity for industries that produce, sale and distribute high volume products that appear in packages and bottles, including the dairy, food, beverage, canning, chemical, health and beauty and pharmaceutical industries.